How to install hurricane windows: Ultimate Guide 2025

Why Hurricane Windows Are Essential for Protecting Your Home

How to install hurricane windows is a critical question for homeowners in hurricane-prone regions like South Florida, where wind-driven rain and flying debris can cause catastrophic damage. The installation process is far more complex than replacing standard windows and requires precise waterproofing, structural anchoring, and strict code compliance to ensure your home’s safety during severe storms.

Quick Answer: The Hurricane Window Installation Process

- Obtain building permits from your local jurisdiction (required by law in Florida)

- Remove existing windows carefully without damaging the surrounding structure

- Prepare the rough opening with a sloped sill and water-resistive barrier (WRB)

- Install sill pan flashing extending 6″ up jambs and 2″ onto the wall surface

- Set and secure the window using approved corrosion-resistant fasteners into structural framing

- Apply flashing tape in “shingle-fashion” layers (sill, then jamb, then head)

- Seal with low-expansion foam and exterior-grade sealant (never seal the bottom flange)

- Pass final inspection to ensure code compliance and maintain insurance coverage

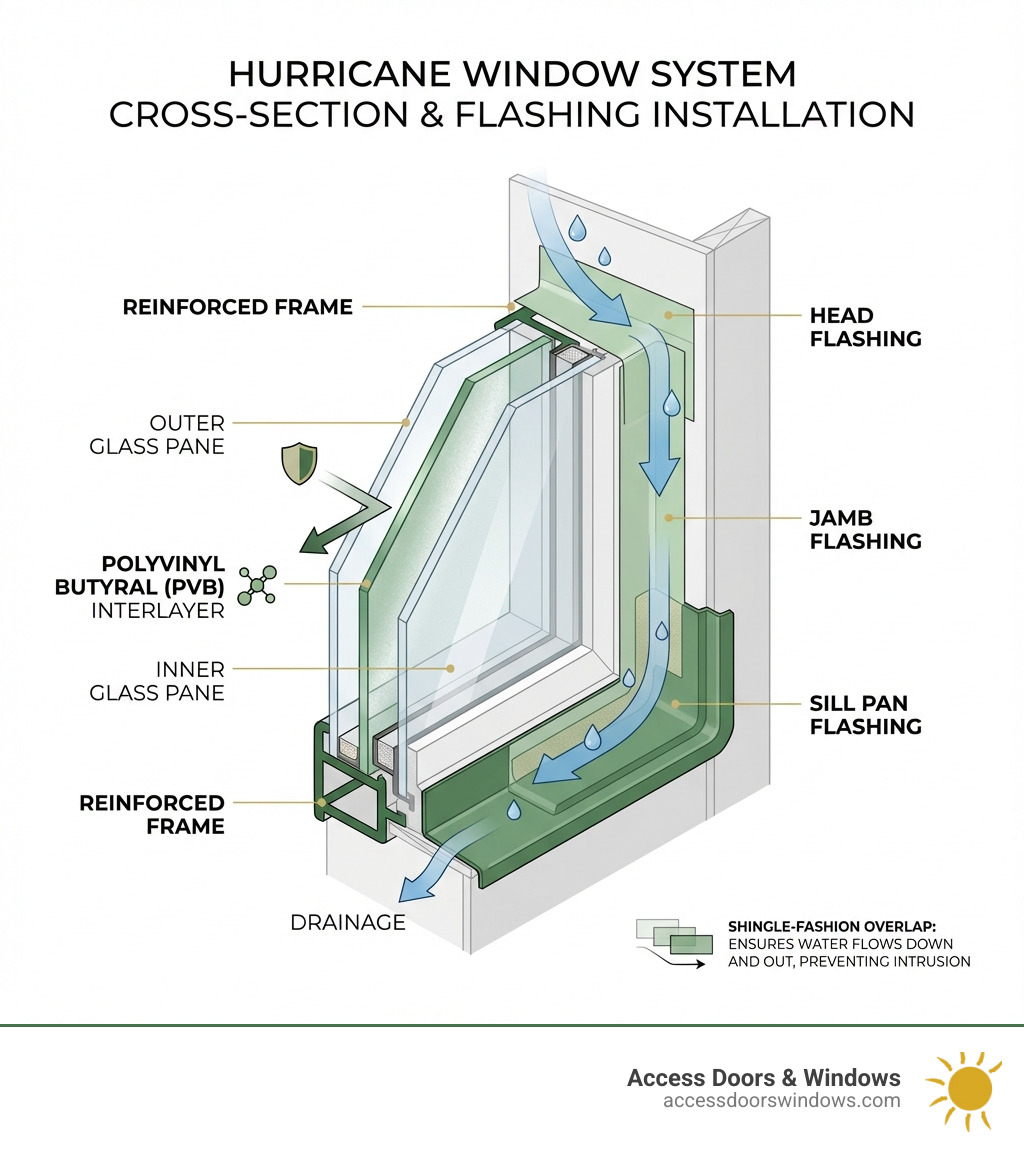

Hurricane windows—also called impact windows—are built with laminated glass containing a polyvinyl butyral (PVB) interlayer that holds shattered glass together even when struck by debris traveling at 50 feet per second. Combined with reinforced frames, these windows can withstand winds up to 200 mph and provide year-round benefits including improved home security, energy efficiency, UV protection, and noise reduction.

However, improper installation can completely negate these benefits. One misstep—like using the wrong fastener, failing to properly flash the opening, or blocking drainage paths—can lead to water intrusion, structural damage, voided warranties, failed inspections, and even loss of insurance coverage during a storm.

The stakes are simply too high for trial and error. While this guide will walk you through every technical detail of the installation process, most homeowners find that hiring a licensed, insured professional installer is the only way to guarantee their family’s safety and protect their investment.

Pre-Installation: Planning, Permits, and Preparation

Before we even think about touching a window, a significant amount of planning, paperwork, and preparation must happen. This crucial groundwork ensures your hurricane window installation project is safe, legal, and built to last in our beautiful, yet storm-prone, Florida communities.

Understanding Florida’s Building Codes and Permits

Florida’s hurricane-prone climate has led to some of the nation’s strictest building codes, especially in coastal counties like Palm Beach, Broward, and Lee. Adhering to these regulations is the first step in any hurricane window installation.

Installing hurricane windows in Florida without a building permit is illegal. The permit process is a crucial safety measure ensuring your installation meets the rigorous Florida Building Code (FBC), including specific wind load ratings and High-Velocity Hurricane Zone (HVHZ) standards. This involves plan reviews and multiple inspections, focusing on details like flashing and sealant use. A final inspection confirms the installation meets manufacturer specifications and is code-compliant.

Skipping permits or failing inspections can result in hefty fines, rework orders, issues selling your home, and voided insurance coverage. Coastal areas like Boca Raton and Fort Myers often require corrosion-resistant stainless steel fasteners due to salt air. These details are vital for your home’s integrity. We steer this complex process to ensure your Impact Window Installation in Florida is fully compliant.

Essential Tools and Materials

Proper hurricane window installation requires specialized tools and approved materials for impact resistance and weatherproofing. Using anything less than these necessities compromises your home’s safety.

Essential tools and materials include:

- Power Tools: Hammer drill (for masonry), impact driver (for fasteners).

- Precision Tools: Laser level, shims, pry bar, caulking gun.

- Weatherproofing Materials: High-quality flashing tape (AAMA 711 compliant), low-expansion foam sealant for windows, and approved exterior-grade sealants.

- Structural Components: Corrosion-resistant fasteners (stainless steel is a must in coastal areas), a sill pan for water drainage, and a waterproof membrane (WRB) or house wrap.

These items are non-negotiable for a durable, code-compliant installation.

Choosing the Right Windows and Understanding Ratings

Choosing the right Hurricane Impact Windows is about performance and protection, not just aesthetics. Key factors include:

- Frame Materials: Hurricane windows need strong frames. Aluminum offers excellent durability and corrosion resistance for coastal areas, while vinyl provides superior insulation.

- Glass Types: All impact windows use laminated glass, where a strong inner layer (PVB or EVA) bonds two sheets of glass. If shattered, the interlayer holds the glass fragments, maintaining the home’s protective seal. Insulated laminated glass adds an extra pane for better thermal performance.

- Energy Efficiency Ratings: Look for ENERGY STAR ratings and certification from the National Fenestration Rating Council (NFRC). Key ratings for Florida’s climate include:

- U-Factor: Measures heat loss (lower is better).

- Solar Heat Gain Coefficient (SHGC): Measures heat gain from the sun (lower is better in warm climates).

- Visible Transmittance (VT): Measures how much light comes through (higher is better for natural light).

Selecting windows with the right combination of these features ensures your investment protects your home from storms while improving comfort and lowering energy bills.

The Step-by-Step Guide on How to Install Hurricane Windows

Now that we’ve covered the crucial planning and preparation, let’s dive into the physical process of how to install hurricane windows. This detailed walkthrough will guide you through each stage, from removing your old windows to securing the new impact-resistant units. While we’re outlining the steps, the precision and expertise required often necessitate professional installation.

Step 1: Accurate Measurement and Old Window Removal

Accurate measurement is the critical first step. Measure each opening’s width and height at multiple points to ensure a perfect fit and avoid costly errors. Once your new windows are ready, the old ones must be carefully removed. This may be a “full frame replacement,” where the entire old frame is removed, or a “pocket replacement” within the existing frame. For optimal protection and structural anchoring, a full frame replacement is often recommended. Our Window Installation Gulf Coast Guide 2025 details these crucial initial steps.

Step 2: Preparing the Rough Opening

The “rough opening” left by the old window requires meticulous preparation. First, clean the opening of all debris and inspect the framing for rot or damage, making repairs as needed. A critical step is ensuring the sill (bottom of the opening) slopes downward to the exterior for proper water drainage. Next, prepare the Water-Resistive Barrier (WRB), or house wrap. This involves specific cuts to create flaps that will integrate with the new flashing in a “shingle-fashion” to manage water flow. The pan flashing, installed on the sloped sill, must extend up the jambs and onto the exterior wall over the WRB, forming the first line of defense against water intrusion.

Step 3: Setting, Shimming, and Securing the New Window

With the opening prepared, the new hurricane window is carefully set in place. Using a laser level, we ensure the window is perfectly level and plumb (vertically straight)—a non-negotiable step for proper function and warranty protection. Shims are used for fine adjustments to support the frame.

The window must be securely anchored into the building’s structural framing (concrete, block, or wood) using approved, corrosion-resistant fasteners like Tapcons. We drill pilot holes and drive fasteners carefully to avoid distorting the frame. Before final fastening, we test the window’s operation to ensure it opens and closes smoothly. This precision is key to an effective and durable Impact Window Installation.

Critical Weatherproofing: Flashing and Sealing Techniques

After the window is physically installed and secured, the next phase is arguably the most critical for long-term performance: weatherproofing. This is where we create an impenetrable barrier against Florida’s relentless wind-driven rain. Proper sealing is the most critical step to prevent water intrusion and costly structural damage, ensuring your investment pays off for decades.

Mastering the “Shingle-Fashion” Flashing Method

The “shingle-fashion” method uses gravity to direct water away from the wall cavity. Each layer of flashing tape must overlap the one below it, creating a continuous drainage plane.

Here’s how we master this method:

- Sill Pan Flashing First: A flexible, self-adhered membrane is applied to the sloped sill, extending up each jamb and onto the exterior wall surface.

- Jamb Flashing Overlaps: Next, jamb flashing is installed over the window flange and the sill pan flashing.

- Head Flashing Last: Finally, head flashing is applied over the window’s top flange, extending past the jamb flashing on both sides to shed water.

- Avoiding Reverse Lapping: The house wrap flap at the top is folded down over the head flashing and sealed to prevent water from getting behind the layers.

This meticulous, layered approach is the cornerstone of a truly watertight hurricane window installation.

Applying Sealant and Interior Insulation

Once the flashing is complete, we apply sealants and insulation to finalize the weatherproofing.

- Exterior Sealant: A continuous bead of high-quality silicone caulk is applied around the top and side flanges. Crucially, we do not seal the bottom flange or weep holes. These openings are vital for allowing any moisture to drain away from the building.

- Interior Air Seal and Insulation: Inside, gaps are sealed with low-expansion insulating foam designed for windows, which creates a thermal and air seal without warping the frame. Finally, interior moldings are installed to complete the seal. Our process ensures your Hurricane Impact Windows Fort Myers FL are not just storm-ready, but also energy-efficient.

DIY vs. Professional Installation: A Crucial Decision

We often encounter homeowners in Fort Myers, Deerfield Beach, and throughout Florida who consider the DIY route for how to install hurricane windows. While the idea of saving money is tempting, this is one project where the risks far outweigh the potential rewards. Installing impact windows is a major structural upgrade, not a simple DIY task like painting a room.

The Risks and Pitfalls of DIY Installation

Let’s be blunt: attempting to install hurricane windows yourself, unless you are a licensed contractor with experience in fenestration systems and Florida building codes, is a gamble with incredibly high stakes.

Here are the significant risks and potential pitfalls:

- Voided Manufacturer Warranty: This is a big one. Most manufacturers, including leading brands like PGT Windows & Doors and CGI Windows, only honor their product warranties when their windows are installed by certified professionals. A DIY installation, even if seemingly perfect, can render your expensive, high-performance windows uninsured by the manufacturer.

- Failed Inspections and Fines: In Florida, installing hurricane windows without a permit is illegal. Even with a permit, if your DIY installation doesn’t meet the rigorous FBC standards—from anchor types and spacing to flashing overlaps—it will fail inspection. This leads to fines, mandatory rework (which can be incredibly costly and disruptive), and could prevent you from selling your home in the future.

- Structural Failure During a Storm: One weak window can create enough internal pressure to blow your roof off during a hurricane. A single misstep—like using the wrong fastener, missing a structural anchor point, or failing to seal gaps—could result in your windows failing during a storm, compromising your entire home’s structural integrity. This is not the time to cut corners.

- Water Damage: Improper flashing and sealing are common DIY mistakes. This can lead to chronic water intrusion, resulting in mold growth, wood rot, and significant structural damage that often goes unnoticed until it’s severe and expensive to repair.

- Specialized Tools and Expertise: You’ll need specialized equipment like hammer drills, impact drivers, laser levels, and specific shimming tools, along with the expertise to use them correctly. The upfront cost and learning curve for these tools can quickly negate any perceived savings.

| Factor | DIY Installation | Professional Installation |

|---|---|---|

| Cost | Appears lower initially, but high risk of hidden costs (rework, fines, damages) | Higher upfront cost, but includes expertise, warranty, and compliance |

| Warranty | Often voided by manufacturers | Guaranteed by manufacturer and installer |

| Code Compliance | High risk of violations, failed inspections, legal issues | Ensured by licensed professionals, permits, and inspections |

| Safety | Significant risk of structural failure, water damage, and personal injury | Maximized safety, structural integrity, and long-term protection |

| Time & Stress | Time-consuming, frustrating, steep learning curve | Stress-free, efficient, handled by experts |

| Tools | Requires purchasing or renting specialized, expensive equipment | Professionals bring all necessary, specialized tools |

When it comes to protecting your family and home, the stakes are simply too high. Our Impact Window Contractors are here to help.

Why Hiring a Licensed Installer is Worth the Investment

Choosing a licensed, insured professional for your hurricane window installation is not just a convenience; it’s an investment in your peace of mind and the long-term safety and value of your home. As a USA Military Family-owned business operating on both Florida coasts, we understand the importance of integrity and meticulous work.

Here’s why professional installation is unequivocally worth it:

- Peace of Mind: Knowing your windows are installed correctly, to code, and ready for whatever Mother Nature throws our way is invaluable. You won’t be second-guessing your work as a storm approaches.

- Warranty Protection: When we install your windows, your manufacturer’s warranty is fully protected. Our installation also comes with its own labor warranty, giving you double the assurance.

- Code Compliance Guaranteed: We handle every local building code, pull all the necessary permits, and ensure your installation is fully compliant and ready to pass inspection in any of our service areas, from Boca Raton to Fort Myers, Palm Beach County to Sarasota County. This means no fines, no forced rework, and no issues when it’s time to sell.

- Proper Tools and Expertise: We bring all the specialized equipment, experience, and training needed for a flawless installation. We’ve spent years learning the difference between Tapcons and wedge anchors, and we know exactly how to achieve a perfect seal and structural anchor.

- Time Savings & Stress Reduction: We handle everything from start to finish, so you don’t have to chase permits, rent tools, or spend your weekends learning complex flashing techniques. You get your weekends back, and we take on the stress.

- Liability Insurance: Accidents can happen. A professional installer carries liability insurance, protecting you from financial responsibility if something goes wrong during the installation process.

Professional installation ensures everything is square, clean, sealed, and built to last. It’s an investment that pays dividends in safety, energy savings, insurance discounts, and increased home value. For the Best Window Installation Company Near Fort Myers and beyond, you can trust our expertise.

Post-Installation: Maintenance, Warranties, and Final Checks

Congratulations! Your new hurricane windows are installed, and your home is more secure than ever. But our job isn’t quite done, and neither is yours entirely. This final section covers what to do after the installation is complete to ensure longevity, performance, and maximum value from your investment.

Post-Installation Checklist and Required Maintenance

After installation, we conduct a final inspection. We encourage you to test each window to ensure it opens, closes, and locks smoothly, confirming proper alignment.

To maintain your windows’ performance and longevity, follow this simple checklist:

- Inspect Sealants: Periodically check exterior sealant for cracks or gaps and repair as needed.

- Clear Weep Holes: Keep the small drainage holes at the bottom of the frame clear of debris to prevent water buildup.

- Clean Regularly: Clean tracks, frames, and glass to ensure smooth operation.

- Check Hardware: Occasionally verify that locks and latches function correctly.

These steps will help your Hurricane Impact Windows Boca Raton FL perform optimally for years to come.

Understanding Warranties, Cost Factors, and Financing

Investing in hurricane windows is a significant decision, and understanding the financial aspects and long-term protections is key.

- Warranties: Professional installation is key to protecting your investment. Most manufacturers’ product warranties are only valid when installed by certified professionals. A reputable installer also provides a labor warranty. Ask if warranties are transferable, as this adds value to your home.

- Cost Factors: The hurricane window installation cost varies based on window size, frame material (e.g., vinyl, aluminum), glass packages (e.g., insulated, Low-E coatings), and installation complexity. A whole-home installation is a significant investment, and we provide transparent estimates.

- Financing Options: We understand this is a major home improvement. Many homeowners use financing to manage the cost. We work with clients to find suitable financing solutions that fit their budget.

Frequently Asked Questions about Hurricane Window Installation

Can hurricane windows withstand a Category 5 hurricane?

Yes, properly installed impact-rated windows are tested to withstand winds over 155 mph and resist impacts from flying debris, meeting standards for Category 5 storms. The key is that the Impact Window Installation must be done correctly to the manufacturer’s specifications.

Is it illegal to install hurricane windows without a permit in Florida?

Yes, in Florida, it is illegal to install hurricane windows without obtaining the proper building permits. This process ensures the installation meets the strict Florida Building Code (FBC) and will pass a final inspection, which is crucial for your safety and home insurance.

How do impact windows improve home security?

The same features that stop flying debris also make impact windows incredibly difficult for intruders to break. The laminated glass with a polymer interlayer will not shatter and fall out like a standard window, providing a powerful deterrent against break-ins and enhancing your family’s security 24/7.

Protect Your Home with a Flawless Installation

Properly installing hurricane windows is a complex, high-stakes project that safeguards your home, family, and investment against severe weather. While understanding the process is valuable, the precision required for waterproofing, structural anchoring, and code compliance makes professional installation the wisest choice. Access Doors & Windows, a licensed and insured installer, ensures every window is fitted to the highest standards for ultimate protection. Ready to secure your peace of mind? Learn about the benefits of hurricane impact window installation.